To bring your visual gear back to life, begin with a careful assessment of the condition. Check for surface scratches and debris on the glass. Using a microfiber cloth for gentle wiping is often effective. If the dirt persists, a few drops of lens cleaner can help. Avoid harsh chemicals that might damage coatings.

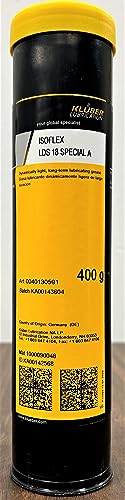

Next, focus on the mechanical aspects. Ensure all focusing and zoom rings move smoothly. If any resistance is felt, applying a small amount of lubricant specifically designed for optics can enhance performance. It’s advisable to stay away from petroleum-based products, as they can harm seals and other components.

Lastly, check for fungus or mold, which can significantly affect image quality. A mixture of distilled water and isopropyl alcohol can be used to clean affected areas. Allow it to dry completely before reassembling. Regular maintenance and proper storage in a dry, cool place will help keep your optical devices in peak condition.

Lens Revival Techniques

Begin with a thorough examination of the optics to identify any scratches or fungus. If fungus is present, prepare a diluted isopropyl alcohol solution for treatment.

- Gently apply the alcohol using a microfiber cloth.

- Wipe in a circular motion, avoiding excessive pressure.

- For stubborn spots, let the solution sit for a few minutes before wiping.

Next, for exterior cleaning, use a soft brush to remove dust and debris. Follow with a moist microfiber cloth dampened with a lens cleaning solution.

- Apply the solution to the cloth, not directly on the surface.

- Wipe the outer barrel and other surfaces to ensure they are free of smudges.

Check the focus mechanism and zoom functionality by rotating and extending the components. If there’s resistance, a light lubricant may be needed. Use a small amount of oil specifically designed for lens mechanisms.

- Disassemble the lens if comfortable, or access it through the mount.

- Apply the lubricant sparingly to gears and moving parts.

- Reassemble carefully, ensuring all parts fit snugly.

Lastly, check for proper alignment. If images are not sharp, minor adjustments may be necessary. Utilize an alignment tool as a reference.

Assessing the Damage on Your Lens

First, examine the outer casing for any noticeable dents or cracks. These physical blemishes can affect both aesthetics and functionality.

Next, inspect the glass elements for scratches or fogging. Use a bright light source to identify imperfections that may not be immediately visible. Scratches can often be felt through a fingertip, while fogging typically indicates internal moisture.

Next, check for fungus or mold, which can appear as cloudy or spots on the glass. A magnifying glass may help you spot these issues more clearly. If found, act swiftly, as they can worsen over time.

Test the lens mechanics by checking the focus rings and aperture blades. Any grinding noises or stiffness could point to internal damage that needs attention. Smooth operation is key for precise shooting.

Finally, evaluate the impact of the detected issues on image quality. Take sample shots at various apertures and focus distances. Analyze the results for softness, distortion, or color fringing. This firsthand assessment will guide you in determining the priority of repairs needed.

Cleaning Techniques for Lens Glass

Use a blower to remove loose dust and debris from the glass surface before any wet cleaning process.

Wet Cleaning Method

I utilize a solution specifically designed for optics; a few drops on a microfiber cloth work wonders. Avoid using household cleaners, as they contain chemicals that can harm the coating.

Follow this approach:

- Apply the cleaning solution to the cloth, not directly on the glass.

- Gently wipe the lens using a circular motion, starting from the center and moving outward.

- Dry with a clean, dry section of the microfiber cloth.

Removing Stubborn Smudges

For more persistent marks, I often use a lens pen equipped with a soft brush on one end and a cleaning tip on the other. Just a tiny dab on the lens is enough to lift the stain without excessive pressure.

Steps to follow:

- Brush dust gently off the surface with the pen’s brush.

- Use the cleaning tip to touch the lens lightly, applying minimal pressure.

- Buff the lens with a microfiber cloth afterward for a polished finish.

Regular maintenance of the glass significantly enhances image quality, so I prioritize cleanliness in all my gear. Keep a lens cleaning kit handy for those spontaneous shots!

Repairing Scratches on the Lens Surface

I frequently encounter minor scratches on optical surfaces, and tackling them requires specific techniques. Begin with a dedicated lens polishing compound or scratch repair kit, designed specifically for optics. Apply a small amount to a soft microfiber cloth and gently rub it over the scratch in a circular motion. Avoid excessive pressure to prevent further damage.

Using Toothpaste for Minor Scratches

An alternative I’ve found effective involves using a mild abrasive like toothpaste. Choose a non-gel variety, apply a tiny amount to a clean cloth, and gently buff the scratch with circular movements for about 30 seconds. Thoroughly clean the surface afterward with a lens cleaner to remove any residue.

Commercial Scratch Removers

If scratches persist, consider professional-grade scratch removers. These products contain finer abrasives, designed for optical glass, and can effectively reduce the visibility of scratches. Always follow the instructions carefully and test on a small area first to ensure compatibility with the lens coating.

After any treatment, re-evaluate the lens by inspecting under a bright light and at various angles to assess the results. If damage remains significant or if the optical integrity is compromised, consult a specialist for potential replacement.

Fixing Fungus and Mold in Optical Gear

To effectively eliminate fungus and mold from your optical equipment, I recommend using isopropyl alcohol (at least 70% concentration) combined with a microfiber cloth for initial cleaning. Gently dab the affected areas rather than rubbing them to avoid scratching the surface.

After treating the visible mold, it’s crucial to address the internal components where spores might remain. For this, disassembling the gear is necessary. Ensure you have the right tools and follow a detailed manual or online guide specific to your model. This step allows for thorough cleaning of the internal elements.

Once disassembled, soak the affected parts in a mixture of isopropyl alcohol and distilled water (1:1 ratio) for a few minutes. This will help dissolve any remaining spores. After soaking, use the microfiber cloth again, ensuring all residues are completely removed.

For persistent mold, a few drops of hydrogen peroxide on a cotton swab can be applied directly to the affected area. However, it’s vital to test this on a small, inconspicuous area first. Allow it to sit for 10-15 minutes, then carefully wipe it away.

| Material | Cleaning Method | Notes |

|---|---|---|

| Lens Glass | Isopropyl alcohol | Use a microfiber cloth to avoid scratches. |

| Interior Elements | Isopropyl alcohol and distilled water | Disassemble carefully to prevent damage. |

| Persistent Mold | Hydrogen peroxide on swab | Test on inconspicuous area first. |

After cleaning, reassemble the components only when you’re sure they are completely dry. Store the equipment in a cool, dry place to prevent mold recurrence, and consider using silica gel packets in your storage area for added moisture control.

Replacing Damaged Lens Elements

Begin by identifying the specific element that requires replacement. Often, it is the front or rear element that suffers damage, leading to significant image quality loss. Take careful measurements of the damaged elements using a caliper or ruler to ensure compatibility with replacement parts.

Source replacement elements from reputable suppliers or manufacturers. Consider compatibility with your specific model, paying attention to parameters such as diameter, thickness, and refractive indexes. Carefully clean the area around the damaged glass prior to removal.

To extract the element, use a lens spanner wrench for nut-style mounts. If the element is glued, gently apply heat with a heat gun to soften the adhesive, which allows for easier separation. Work cautiously to avoid additional damage to surrounding components.

Once the damaged component is removed, proceed to insert the new one. Ensure alignment and fit before securing it back in place. If adhesive is required, use an optical-grade adhesive suitable for the materials of both the lens and the mounting structure. Allow adequate time for curing before testing.

After assembly, conduct a thorough inspection of optical quality, checking for alignment and clarity through a lens test chart. Evaluate performance in various lighting conditions to confirm the success of the replacement.

| Step | Description |

|---|---|

| 1 | Identify the damaged element and measure it accurately. |

| 2 | Source replacement components from trustworthy suppliers. |

| 3 | Remove the damaged element using appropriate tools and techniques. |

| 4 | Insert the new element and secure it with suitable adhesives. |

| 5 | Inspect the completed assembly for optical quality and alignment. |

Adjusting Focus Mechanism Issues

Identify any misalignment in the focus mechanism by gently rotating the focus ring and observing its movement. If it feels stiff or unresponsive, disassemble the unit carefully, noting the position of each component for reassembly.

Check for debris or damage around the focus threads. Clean and lubricate the threads using a small amount of camera lens grease to enhance smoothness. Avoid excess lubricant, as it can attract dirt.

Inspect the focus system’s gears and levers for wear. If necessary, replace any damaged parts. For precision alignment, I utilize calipers to measure and restore the original configuration.

Periodically test the adjusted focus by mounting the lens on a camera. Capture images at various distances to ensure the mechanism operates correctly across the entire range.

In cases where the focus is still off, adjusting the internal components may be necessary. Use a calibration tool or software to help realign and achieve pinpoint accuracy.

Finally, consider checking for firmware updates for your camera, as software enhancements can also improve focus performance.

Re-sealing Weatherproof Lenses

To maintain the integrity of weather-resistant optics, I follow a precise re-sealing technique. First, gather the necessary tools: precision screwdriver set, silicone sealant (preferably waterproof), a soft cleaning cloth, and isopropyl alcohol.

Begin by disassembling the lens carefully, paying close attention to the sequence of components. Take photographs for reference, ensuring proper reassembly later. Clean all surfaces with isopropyl alcohol to remove any old sealant or debris.

Once clean, inspect the old seals for degradation. Remove any damaged seal material using a soft cloth or a plastic scraper to avoid scratching surfaces. I then apply a fresh bead of silicone sealant, ensuring an even application along the mating surfaces.

Reassemble the components, applying gentle pressure to ensure a secure fit and allowing the sealant to cure as per the manufacturer’s instructions. Be cautious with the tightening of screws; overtightening can create stress and misalignment.

Finally, allow sufficient time for the silicone to cure completely before testing the lens in various environmental conditions. Store the lens with silica gel packs to absorb excess moisture, further protecting my investment.

Tips:

- Always work in a dust-free environment to prevent particles from getting trapped in the seal.

- Consider calibrating the focus mechanism post-reassembly for optimal performance.

- Regularly check and reapply sealant as needed, especially before extreme weather conditions.

Testing Optical Performance After Restoration

Utilizing test charts is a reliable method for evaluating sharpness and resolution. I recommend setting up a high-contrast target at a distance appropriate for the focal length. Capture images at various apertures to determine optimal performance across the spectrum. Pay attention to corner sharpness, as imperfections often manifest away from the center.

Another approach involves checking for chromatic aberration. I examine the edges of high-contrast subjects in both color and black-and-white settings. This helps identify any lingering optical flaws. A software tool can assist in analyzing images, revealing color fringing that might not be visible to the naked eye.

Distortion and Vignetting Assessment

To evaluate distortion, I photograph straight lines and assess their curvature within the frame. This step is particularly vital for wide-angle designs. Use software to analyze the captured images for barrel or pincushion distortion.

For vignetting, I capture images of uniformly lit surfaces at various apertures. Comparing exposure levels across the frame facilitates identification of light fall-off. Adjustments may be required to optimize performance.

Real-World Test Shots

Conduct field tests under various lighting conditions. Capture images in natural and artificial light to analyze how well the optics handle different scenarios. Observe bokeh quality and color rendition; these factors are crucial for user satisfaction. In addition, reviewing images at 100% magnification will reveal any remaining flaws that could affect overall image quality.

Maintaining Your Restored Lens

Proper storage is key. I keep my rehabilitated optics in a protective case, preventing dust accumulation and minimizing the risk of inadvertent scratches. Silica gel packets help control humidity, which is vital for preserving internal components.

Regular cleaning is crucial for optimal performance. I use a soft microfiber cloth to gently wipe the outer glass and avoid touching the lens elements directly with my fingers. For stubborn spots, I apply a few drops of lens cleaning solution to the cloth, ensuring no liquid seeps into the interior.

Routine Checks

I conduct periodic inspections for signs of fungus or moisture buildup. If I notice any unusual spots, I immediately address them using the techniques outlined previously. It’s wise to assess the focus mechanism regularly as well, making adjustments if any stiffness or misalignment becomes apparent.

Care During Use

During shoots, I use a lens hood to shield against flare and impact. I avoid exposing my optics to extreme temperatures or sudden changes in environment, as this can compromise seals. Finally, I always carry a protective cap to cover the front element when the glass is not in use.