I recommend using a specific type of lubricant that will be highly beneficial for your optical gear maintenance. In this article, I will cover the top choices available on the market, including their features and formulations, allowing you to make an informed decision.

This piece targets photographers, videographers, and anyone who relies on high-quality visual equipment. Understanding how to care for your optics will enhance their longevity and performance, ultimately improving the quality of your work.

I’ll provide a concise overview of several leading products, discussing their pros and cons, application methods, and unique qualities. By the end, you’ll have a clear idea of which lubricants will best suit your gear and enhance its functionality.

Best Lubricant for Optical Equipment

I recommend selecting a lubricant that is specifically designed for precision optical devices. It is essential to choose a formulation that is non-damaging to the components involved, such as glass and metals. A good choice will ensure smooth focusing while preventing dust and debris accumulation.

When considering the right substance, pay attention to the viscosity and the composition. For optimal performance, a lightweight and residue-free product is ideal. Avoid any grease that can thicken or harden over time, as this will hinder functionality and may lead to more significant maintenance issues in the future.

Characteristics to Consider

Here are some key attributes to examine:

- Compatibility: Ensure it can be safely used with both metal and plastic components.

- Resistance to Environmental Factors: Look for options that resist moisture and temperature fluctuations.

- Longevity: A product that maintains its properties over time is preferable to minimize reapplication.

- Non-conductive: This prevents any risk of electrical issues within the equipment.

Before application, always clean the surfaces to remove any old lubricant or debris. Proper application is crucial; apply a thin layer to prevent excess that could cause problems. Testing the movement after application ensures the desired smoothness is achieved.

Lastly, consult user manuals or trusted sources for guidance on lubrication practices specific to each piece of equipment. Regular maintenance will enhance the longevity and performance of your optical tools.

Understanding the Role of Lubricants in Lens Mechanisms

In the mechanics of optical systems, lubricants play a critical role in ensuring smooth operation of the various moving parts. Properly chosen substances can minimize friction, allowing for precise adjustments in focus and zoom capabilities, which translates into better functionality and overall performance.

It’s important to recognize that not all lubricants are created equal. The selection depends greatly on the type of materials used in the lens assembly and the environmental conditions in which the optical instruments are employed.

The Functions of Lubricants in Optical Systems

Lubricants in optical devices serve several key functions:

- Friction Reduction: They minimize wear and tear on moving parts, prolonging the lifespan of components.

- Temperature Stability: Quality substances can maintain their properties across a wide temperature range, ensuring reliable performance.

- Dust Protection: A well-applied lubricant can create a barrier against dust and debris, which can otherwise interfere with optical clarity.

When choosing a lubricant, it’s crucial to consider compatibility with the materials in the lens assembly. For example, silicone-based options might be preferable in certain situations, whereas other high-performance synthetic compounds could offer superior stability and longevity.

In conclusion, the role of lubricants in optical systems is multifaceted and significant. Understanding the specific needs of the lens mechanism can lead to better maintenance and improved overall performance.

Top-Selling Lubricants for Optical Equipment

When maintaining precision instruments, choosing the right lubricants can significantly impact their performance. The right substances ensure smooth operation and longevity of moving parts, which is essential for optimal function.

I recommend considering options that ensure compatibility with optical materials. Many lubricants exhibit properties that reduce friction while preventing damage to delicate components. It’s crucial to select formulations that do not degrade plastics or interfere with coatings.

Characteristics of Preferred Lubricants

- Viscosity: A lubricant with the correct viscosity prevents wear and tear while allowing for easy movement.

- Non-toxicity: Selecting safe, non-toxic substances protects the components and the user.

- Temperature Resistance: Lubricants that maintain integrity under various temperatures will ensure consistent performance.

- Water Resistance: These formulations prevent moisture damage and extend the lifespan of optical equipment.

Conduct testing with various lubricants to find the most suitable one for specific equipment. Regular maintenance with the selected lubricant keeps the optical instruments functioning smoothly and mitigates potential damage over time.

When in doubt, seek advice from industry professionals or consult relevant manuals to make informed choices about lubricants tailored to your specific optical devices.

Key Ingredients for Optimal Lubrication

Choosing the right composition for sliding mechanisms in optical devices is essential. The formulation must ensure smooth operation while protecting against wear and environmental factors.

One of the primary components I’ve identified is a silicone-based compound. This choice remains stable across a broad temperature range and offers excellent resistance to moisture, minimizing the risk of corrosion. Another ingredient to consider is a high-performance synthetic oil, which can enhance fluidity and longevity, especially in high-stress scenarios.

Additional Factors to Consider

When blending formulations, I’ve found the following factors play a significant role:

- Viscosity: A balanced viscosity guarantees that the lubricant stays in place without being too thick, preventing accumulation that could hinder operation.

- Additives: Incorporating anti-wear agents can extend the life of the components by forming protective layers that reduce friction.

- Compatibility: Ensuring the lubricant is compatible with materials used in optical instruments prevents degradation of seals and housing.

In summary, choosing a combination of silicone and synthetic oils, paying attention to viscosity and formulation compatibility, can significantly enhance the performance and longevity of moving parts within optical devices.

Application Techniques for Camera Lens Lubricants

To ensure smooth operation of the focus and zoom mechanisms, proper application techniques are necessary when using lubricants. I recommend starting with a clean surface by removing any old residue with a microfiber cloth or a specialized lens cleaning solution. This prevents contamination and enhances the effectiveness of the new lubricant.

Next, I apply a small amount of the lubricant to a clean application tool, such as a fine brush or a cotton swab. It’s crucial to use minimal product, as excess can attract dust and debris. Carefully focused application directly to the moving parts is key to maintain optimal functionality.

Techniques

-

Targeted Application:

I focus on areas where friction is most likely to occur, applying the product in thin, even layers to ensure a consistent coating.

-

Even Distribution:

With gentle movements, I spread the lubricant evenly, avoiding clumps that may hinder movement.

-

Wipe Excess:

After application, I carefully wipe away any excess product from external surfaces to maintain cleanliness and prevent buildup.

Lastly, I allow the lubricant to settle for a few minutes before reassembling the components. Performing a simple test to check for smoothness is essential. If it feels stiff, I may need to readjust the application.

Preventative Maintenance: When to Reapply Grease

It’s advisable to check and, if necessary, reapply lubrication at least once a year, depending on usage and environmental conditions. Regular inspections help to identify any signs of wear or degradation early, ensuring optimal performance and longevity of the equipment.

If I notice any stiffness or unusual resistance in zoom or focus mechanisms, it’s a clear indication that it’s time to refresh the lubricant. Environmental factors, such as humidity and temperature fluctuations, also play a significant role in the degradation of the lubricant. In harsher conditions, more frequent application may be needed.

Signs Indicating It’s Time for Lubrication

- Difficulty in Movement: If I experience resistance in smooth operations, it’s a strong signal to reapply.

- Noisy Components: Unusual sounds during focusing or zooming often indicate dried-out lubrication.

- Visible Wear: Dirt or debris accumulation around the moving parts can lead to grime, which requires cleaning and reapplication.

- Changes in Performance: Any decline in the speed or precision of movement is worth investigating.

Additionally, using high-quality substances can extend the intervals between applications. I often prefer products specifically formulated for precision mechanics, as they can maintain their properties longer. Regular maintenance not only preserves functionality but also enhances the overall user experience, allowing for seamless captures.

Environmental Considerations in Lubricant Selection

Choosing a lubricant for optical instruments involves assessing its environmental impact. Opt for products that reduce ecological harm while ensuring mechanical reliability and longevity.

Look for biodegradable options made from plant-based ingredients. These alternatives minimize pollution and support sustainable practices.

- Biodegradable formulations: Choose lubricants that break down naturally over time.

- Low toxicity: Consider substances that pose minimal risk to wildlife and ecosystems.

- Recyclable packaging: Favor products packaged in materials that can be recycled or reused.

- Manufacturer practices: Research companies committed to environmentally friendly production methods.

By prioritizing these factors, I contribute to the preservation of natural resources while maintaining the functionality of my tools.

Best grease for camera lenses

Features

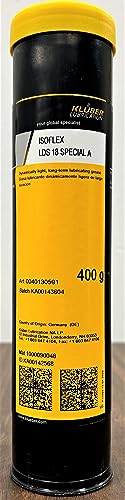

| Part Number | 004013-591 |

| Size | 400g |

Features

| Part Number | 1658832 |

| Is Adult Product |

FAQ:

What are the best types of grease to use for camera lens maintenance?

When it comes to maintaining camera lenses, a few specific types of grease are recommended. First, a silicone-based grease is often used because it provides smooth operation without attracting dust and particles. Another option is a molybdenum disulfide grease, known for its excellent lubrication properties and resistance to wear. For more specific applications, like in zoom lenses, a lighter, non-sticky grease might be favored to ensure that the lens mechanism moves freely without any obstruction. Be sure to choose a product that is designed for optical equipment to avoid any potential damage to the lens coatings.

How can I properly apply grease to my camera lenses without causing damage?

Applying grease to camera lenses requires careful attention to detail to prevent any harm. Begin by thoroughly cleaning the lens area to remove dirt and old grease. Use a lens cleaning solution and a microfiber cloth for this task. Once clean, apply a small amount of grease to a lint-free applicator or a soft brush, targeting only the parts that require lubrication, such as the guide rails or inner threads. It’s important not to over-apply the grease, as excess can attract dust and create a mess inside the lens. After applying, gently move the lens mechanism to distribute the grease evenly. Regularly check for any build-up of residue and clean as necessary to maintain optimal performance.