For those seeking to restore their optical equipment, I can confirm that the option for refurbishment is viable. Many brands and independent service centers offer comprehensive repair services tailored to various types of optics, ensuring they regain functionality and performance.

I recommend contacting authorized service stations as they possess the expertise and genuine parts necessary for high-quality repairs. This ensures that your device is handled with care and restored to its original specifications.

Consider discussing specific issues with technicians, as they can provide insights into the condition of your equipment and potential costs associated with the restoration process. Preparing a list of symptoms or problems may streamline this consultation, allowing for more efficient troubleshooting.

Inquire about warranties on repaired items, as reputable service centers typically offer guarantees on their workmanship and parts. This can provide added peace of mind when investing in restoration services.

Lens Repair Services Offered by Nikon

Nikon provides a specialized service for the restoration of their optical gear, focusing on repairs that can enhance or restore functionality. Clients needing assistance can expect comprehensive evaluation and repair options, depending on the damage or wear.

What Repair Options are Available?

- Cleaning: Dust and moisture can impair image quality. A thorough cleaning helps ensure optimal performance.

- Element Replacement: If a specific component, such as a front or rear element, is damaged, replacement is often possible.

- Focusing Mechanism Adjustment: Ensuring accurate autofocus capabilities is crucial; adjustments are made to the mechanism where necessary.

- Calibration: After repairs, calibration is performed to maintain image quality and precision.

How to Access Repair Services

To utilize the restoration services, it’s advisable to contact Nikon support directly through their official website. They provide detailed instructions for shipping or visiting a service center. Always check the warranty status for possible coverage on repairs.

For expedited service, keep all documentation and receipts related to your optics. Clearly outline the symptoms or issues you’re experiencing to facilitate a more efficient evaluation process.

Understanding Nikon’s Lens Repair Policy

I recommend checking Nikon’s official website for the most accurate information regarding their lens servicing options. Their policy typically covers various types of repairs, from minor fixes like cleaning to more extensive work involving parts replacement. Each case requires evaluation, and they provide an estimate based on the condition of the product.

Service Process Details

Upon sending your optics in for service, you can expect a confirmation of receipt. A technician will assess the condition and communicate the repair costs and estimated turnaround time. It’s crucial to maintain open communication; I often follow up to ensure I’m updated on any developments or if additional repairs are necessary.

Warranty Considerations

If your item is under warranty, many repairs related to manufacturing defects may be covered. Always have proof of purchase ready, as it can expedite the process. Keep in mind, accidental damage may not be included under standard warranty coverage, so I recommend reviewing the warranty terms closely.

Types of Repairs Offered by Nikon

My experience with Nikon’s repair services has shown that they provide several types of fixes tailored to various issues.

- Optical Adjustments: These involve calibration and alignment of elements within the optical mechanism to ensure image clarity.

- Surface Repairs: Scratches or dents on the exterior can be smoothed out or polished, restoring the equipment’s appearance.

- Mechanical Repairs: Malfunctions in the mechanical aspects, such as focusing mechanisms or aperture blades, are addressed through thorough inspection and component replacement if necessary.

- Electronic Repairs: Issues related to circuitry or digital interfaces are diagnosed and repaired, securing proper functionality of electronic aspects.

- Cleaning Services: Comprehensive cleaning of both internal components and outer surfaces is offered, critical for maintaining optimal performance.

I recommend checking specific guidelines before deciding on any repair, as conditions may vary based on location and type of product. It’s also beneficial to confirm warranty status, as some repairs may be covered. Regular maintenance can prolong the life of your optics considerably.

Common Lens Issues That Require Repair

Focus issues like front focus or back focus can result in blurry images. A calibration may be necessary to resolve these discrepancies. If you notice this problem, it’s best to check the lens on multiple bodies to confirm that the lens itself is faulty.

Dust and debris trapped within optical elements can lead to soft images and reduce contrast. Regular cleaning can mitigate this, but if particles cannot be removed through routine maintenance, a professional disassembly might be required.

Brittle or fungus-infested coatings can significantly degrade image quality. While minor cleaning may help, persistent cases will need thorough treatment or replacement of the affected elements.

Mechanical failures, such as aperture blades sticking or failing to open/close, can disrupt exposure settings during shooting. If you experience inconsistent exposures, inspecting the mechanism should be a priority.

Autofocus malfunctions can severely affect your ability to capture sharp images. If the mechanism fails to lock onto a subject or produces erratic focus points, servicing the autofocus system will often be necessary.

Physical damage like scratches on the front or rear elements can lead to unwanted flares or loss of detail. Depending on the depth of the scratch, polishing or element replacement might be required.

Loose or detached mounts can also cause alignment issues, preventing accurate attachment to the body. Tightening or re-attachment by a skilled technician is essential in such cases.

Finally, compatibility problems with newer camera bodies may arise due to firmware discrepancies. Updating the firmware can often resolve these issues without the need for repair. Always check the manufacturer’s website for available updates before seeking professional help.

How to Identify Damage on Your Nikon Lens

Inspect the exterior for any signs of physical injury such as cracks, dents, or loose parts. Pay close attention to the barrel and focusing mechanism, as any misalignment may impede operation.

Check the glass elements for scratches, fungus, or haze. Use a bright light to inspect the lens surface from various angles. Utilize a microfiber cloth to gently clean the outer glass, but avoid deep cleaning without proper tools, as this can exacerbate existing issues.

Test the autofocus functionality by observing how quickly and accurately it locks onto subjects. Any hesitancy or failure indicates a potential problem with the internal mechanisms.

Look for any unusual noises when zooming or focusing, such as grinding or rattling. These sounds often signify loose components or foreign objects within the assembly.

Examine the aperture blades through the lens. They should open and close smoothly. If they are sticky or fail to operate, this points to internal lubrication issues or mechanical faults.

Perform a thorough test shot in a controlled setting. Evaluate the images for sharpness, contrast, and color accuracy across different apertures and focal lengths. Any visible distortion, soft edges, or color fringing may signal underlying problems.

Be observant to any changes in performance during use. If you notice any drastic shifts in quality or functionality, it is advisable to seek professional evaluation.

Evaluating Cost of Lens Repair at Nikon

To assess the repair expenses for optical devices, I recommend starting with an online estimate tool available on the manufacturer’s website. Typically, repair costs can vary based on the type of service required and the specific model. It’s prudent to accumulate information regarding common issues and their associated repair charges.

I find that repairs can range widely. For a basic fix, charges may begin at around $100, while more complex repairs can exceed $300. Here’s a brief overview of typical repair costs:

| Repair Type | Estimated Cost |

|---|---|

| Focusing Mechanism Adjustment | $100 – $150 |

| Element Replacement | $150 – $300 |

| General Servicing | $75 – $125 |

| Sealing and Weatherproofing | $100 – $200 |

Insurance may cover some repair costs, but it’s essential to verify with your provider. Additionally, it’s advisable to keep all documentation and receipts for repairs. This may assist in future claims or warranties.

I recommend contacting customer service for detailed estimates and the availability of necessary parts. Ensure that you receive a clear breakdown of potential charges before committing to any repairs. This transparency can help avoid unexpected expenses.

Steps to Send Your Lens for Repair

First, gather all necessary materials: the damaged object, its original packaging if available, and a detailed description of the issues faced. Ensure you include your contact information and a copy of your proof of purchase.

Next, locate the service center’s website to access the specific repair form. Complete this form thoroughly, detailing the problems with the optical device. This information aids technicians in assessing the situation efficiently.

Prepare the package for shipping. Use protective padding to prevent damage during transit. I recommend a sturdy box that can withstand handling. Seal the package securely to avoid any opening during transportation.

Choose a reliable courier service with tracking options. Insure the package if the item’s value is high; this provides peace of mind during the shipping process. Keep the shipping receipt as proof of dispatch.

Once the item arrives at the service center, monitor repair status through the provided tracking system or contact the service team for updates. They’ll inform you about the estimated time frame for repairs and potential costs.

When the repair is completed, ensure to review the work done and verify that the functionality meets your expectations. If any issues arise after receiving it back, reach out to the service team promptly for further assistance.

Timeframe for Lens Repairs

For efficient processing, sending in your optic unit often results in a turn-around time between 2 to 4 weeks. This duration can vary based on factors such as the extent of damage and parts availability.

Consider checking the service center’s online portal for any updates regarding your submission. This can provide insight into where your item stands in the repair process.

If repairs are extensive or require parts that are not readily available, delays may occur. In such cases, keeping communication open with the service team helps to manage expectations.

For urgent situations, inquire about any expedited service options that might be available, although additional fees may apply. Being proactive by detailing the issue clearly during submission can aid in expediting the process.

Warranty Considerations for Nikon Lenses

Be aware of the warranty terms specific to your optical instruments. Generally, repairs under warranty provide coverage for manufacturing defects but exclude normal wear and tear or accidental damage. It’s advisable to register your product upon purchase to ensure your coverage is active.

Review the duration of the warranty period; most offerings range from one to two years, depending on the type of product. Always keep the original receipt as proof of purchase, which may be required to process any claims.

| Warranty Type | Coverage Details | Exclusions |

|---|---|---|

| Limited Warranty | Manufacturing defects, parts and labor | Accidental damage, misuse, or modifications |

| Extended Warranty | Additional coverage after standard warranty period | Similar exclusions as limited warranty |

To ensure optimal handling of your claim, utilize the appropriate service centers outlined in the warranty documentation. Check the specific process for initiating a warranty repair, as it may differ from regular repair submissions. It’s wise to document all communication related to your warranty claim for reference.

Keeping your optical equipment properly maintained may also extend its lifespan and reduce the likelihood of repairs. Store in a safe, dry place, and consider periodic professional check-ups, even outside the warranty period, to maintain performance.

How to Extend the Life of Your Nikon Lens

Clean the exterior and glass regularly using a microfiber cloth. Avoid using harsh chemicals that can damage coatings.

Proper Storage Techniques

- Keep your glass in a dry environment to prevent moisture buildup.

- Use a padded case for transport and protection against impacts.

- Store upright to prevent pressure on the glass elements.

Regular Maintenance Practices

- Inspect the focusing mechanism and zoom operation periodically for smoothness.

- Use a lens cap when not in use to prevent scratches and dust accumulation.

- Check for any signs of fungus or dirt inside the barrel and seek professional cleaning if necessary.

Be mindful of temperature changes which can affect lubrication within the components. Allow your equipment to acclimate gradually to avoid condensation.

Handling Recommendations

- Use both hands when mounting or detaching from the body to reduce stress on the connections.

- Avoid pointing your gear towards direct sunlight for prolonged periods to prevent overheating.

Consider using protective filters to absorb potential scratches or impacts on the front element. Regularly verify that these filters are clean and free of any obstructions.

DIY Troubleshooting for Nikon Lens Problems

I often tackle issues with my optical gear myself before considering professional service. Here’s a straightforward approach to diagnosing common complications.

Common Issues to Inspect

Start by checking for these frequent problems:

- Focusing difficulties: Ensure the focus mechanism is clean and free of debris.

- Unusual sounds: Listen for grinding or clicking noises when adjusting.

- Fuzzy images: Examine the glass for dust, scratches, or internal fogging.

- Zoom stiffness: Lubricate the zoom ring with appropriate materials

Tools and Techniques

Use the following tools to assist in your troubleshooting:

| Tool | Purpose |

|---|---|

| Microfiber cloth | For cleaning the exterior and glass surfaces. |

| Air blower | To remove dust from internal components and lens mounts. |

| Screwdriver set | For opening the lens casing if necessary. |

| Lens cleaning solution | To safely clean optics without damage. |

If the issue persists after these checks, it may be time to seek professional assistance, especially for complex repairs. Trying to fix intricate mechanisms without proper knowledge can lead to further damage, so exercise caution.

Common Myths About Lens Repairs

Many believe that repair options are limited after certain damages occur, but that is often not true. A range of issues can be resolved through professional services if the lens is not beyond repair.

Another misconception is that repair processes take an exceedingly long time. In reality, turnaround time can vary, but most repairs can be completed within several weeks, depending on the complexity of the issue.

Some think that using third-party services will save money, but this can lead to further problems. Authorized repair centers typically ensure quality and compatibility with original parts, which is often not the case with unofficial repairs.

There’s also the idea that every repair is prohibitively expensive. Many fixes are surprisingly affordable, especially when compared to the cost of purchasing new equipment. Costs often depend on the specific problem and required parts.

People frequently assume that maintenance is unnecessary if there haven’t been visible damages. However, routine check-ups can prevent minor issues from escalating and save money in the long run.

Operating under the belief that every lens problem can be fixed can be misleading. While many issues can be addressed, some damages, like severe optical misalignment or significant physical trauma, may render items irreparable.

Some users think warranties cover all types of damage. However, warranties often do not cover physical damage caused by mishandling or accidents, so understanding the terms is crucial.

Understanding Nikon’s Parts Availability

When seeking replacements for components, I found that the availability at the manufacturer often varies based on the age and model of the optical device. Typically, for recent models, spare parts are readily sourced. However, for older devices, it may become challenging to locate certain specifics.

Current Parts Supply Situation

Throughout my experience, I discovered that the company maintains a catalog of parts that are generally accessible for newer releases. It’s prudent to check the official website or contact support for the latest inventory updates. Parts such as focus motors, optical elements, and mount components are often stocked, while vintage items may require more time to procure or might not be available at all.

Ordering Replacement Components

Ordering necessary parts can be executed through authorized service centers. I’ve noted that directly reaching out to a service center can yield the quickest response. Keep in mind that part pricing can vary, influenced by labor and urgency of the required service.

| Part Type | Availability | Estimated Wait Time |

|---|---|---|

| Modern Focus Motor | Readily available | 1-2 weeks |

| Optical Element for New Models | In stock | 1 week |

| Vintage Components | Limited | Variable (up to several months) |

By addressing part availability proactively, it is possible to manage repairs more effectively. Being informed about the likelihood of sourcing specific components can streamline the entire repair process.

Rebuilt vs. New Optics: A Comparison

Choosing between refurbished optics and brand-new alternatives hinges on several factors, particularly usage and budget. Refurbished optics typically offer significant savings and can perform almost as well as new counterparts. However, they may not come with the same warranty or assurance of longevity.

New equipment usually features the latest technology, often including improved glass and coatings. While this results in better image quality, the price point is considerably higher. For users who require optimal performance and reliability, the investment in new gear is justifiable.

Refurbished models may suffice for hobbyists or those on a tight budget, provided they are sourced from credible retailers with a solid reputation for quality control. Checking reviews and warranty offers is advisable when considering refurbishment.

Additionally, keep in mind the resale value. New models generally retain better resale value compared to refurbished versions, making them a smarter financial choice in the long run for serious enthusiasts and professionals.

Ultimately, the decision boils down to balancing budget constraints with personal requirements for performance and reliability. Evaluating your needs honestly will guide you to the best choice for your photography pursuits.

What Happens to Old Lens Parts?

I often wonder about the fate of components from older optical devices after they’ve been deemed unusable or outdated. Generally, manufacturers have specific processes for handling these parts.

Recycling and Repurposing

Many manufacturers utilize a recycling strategy for elements that are no longer viable for use in new products. Here are some common practices:

- Material Recovery: Glass and metals are frequently melted down and repurposed for new optical and mechanical applications.

- Component Reuse: Certain parts, if in good condition, may be refurbished and used in other products or repairs.

Obsolescence and Innovation

As technology advances, older components may be permanently retired. However, this often paves the way for innovative designs. Key points include:

- Legacy Support: Companies sometimes provide support for older models, allowing for parts to remain available.

- Research and Design: Failures and successes from older devices contribute to the development of more advanced products.

Ultimately, while many parts may disappear from circulation, their impact influences future design and technology in significant ways.

Nikon’s Lens Calibration Process Explained

I recommend understanding the lens calibration procedure to ensure optimal performance. This process involves precise adjustments to maintain sharpness, focus accuracy, and overall image quality. Typically, the service begins with a thorough inspection to identify any misalignments or defects.

The next step focuses on adjusting the autofocus system. This includes fine-tuning the lens elements to guarantee they align correctly with the camera sensor. A series of tests usually accompanies this calibration to verify that focus targets are being accurately met at various distances.

The repair team utilizes specialized equipment to calibrate the lens against established standards. This can involve the use of optical benches, which allow for precise measurements of lens performance. Adjustments are made as necessary based on the readings obtained from these tests.

<p.Another key aspect of calibration involves checking for distortion and chromatic aberrations. These factors can significantly impact image quality. After completing adjustments, final tests are performed to ensure that all parameters meet the manufacturer's specifications.

<p.For anyone experiencing issues like inconsistent focus or soft images, I recommend directly contacting an authorized service center for a thorough evaluation. Proper calibration can restore performance and extend the lifespan of the optical device.

Customer Experiences with Nikon’s Repair Service

I’ve had varied interactions with the repair service for lenses and the experiences can differ significantly based on issues encountered. Many users express satisfaction when repairs restore their equipment to original functionality, highlighting the meticulous attention to detail during the servicing process.

Several customers reported smooth communication throughout the repair timeline. They appreciated receiving updates via email or phone, ensuring they were informed about the stages of the repair. This was particularly reassuring for those who have had urgent projects reliant on their gear.

Cost transparency is another aspect commonly praised. Many shared that they found the pricing structure fair, especially considering the quality of work. It’s important to read all estimates carefully, as additional repairs may be suggested, but this is often beneficial in the long run.

I noticed that timelines can vary; while some lenses were returned quickly, others took longer due to parts availability. Those who expected longer wait times were generally more understanding, especially when notified early in the process.

Individuals with more severe damage often expressed relief when their lenses were brought back to life, emphasizing the skill involved in addressing complex issues. I found it helpful to share detailed descriptions of problems while submitting items for repair, as it seemed to expedite diagnosis and service.

Overall, negative experiences are relatively rare. Users who encountered challenges primarily mentioned unresponsiveness in the early stages of communication or delays without updates. However, most indicated that once contacted, the resolution process was handled well.

Alternative Repair Options for Nikon Lenses

I recommend exploring third-party repair services if you seek alternatives for lens restoration. Numerous local and online repair shops specialize in optical equipment, often providing competitive pricing and varied turnaround times. Research customer reviews and ratings to gauge reliability.

Independent Technicians

Consider independent technicians who have experience with optical repairs. Many have served in authorized service centers and possess the necessary skills to fix issues. Asking for a quote and turnaround time can help compare these options to manufacturer services.

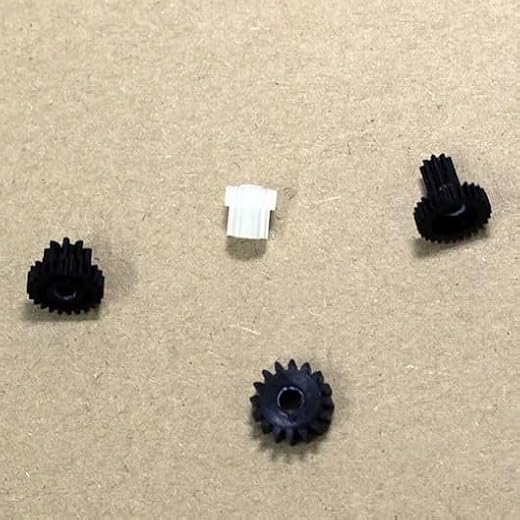

DIY Repair Kits

If you are comfortable with hands-on work, various DIY repair kits are available for minor problems like loose elements or stuck zoom mechanisms. Ensure you read user feedback and guidelines carefully before attempting repairs to avoid further damage.

How to Choose a Third-Party Repair Service

Research extensively before selecting a repair provider. Start with online reviews, focusing on customer feedback about expertise and service quality.

Prioritize warranty coverage. A reputable repair service should offer a warranty on repairs performed, ensuring peace of mind regarding workmanship.

Assess the qualifications of technicians. Look for certifications or specific training relevant to the brand and model of your optical devices.

Inquire about parts sourcing. High-quality repairs depend on the availability of genuine or reliable aftermarket components.

Consider turnaround time. Confirm expected repair durations, as delays can affect your projects.

Request cost estimates. A transparent pricing structure is essential, including potential additional costs for unexpected repairs.

Look for a service with a robust communication policy. They should provide updates on repair status and be readily available to answer questions.

Check for experience with your specific device type. Specialized knowledge can significantly improve the diagnostics and repair process.

If possible, visit the shop physically. This allows you to assess their professionalism and organizational standards directly.

Lastly, ask for referrals from photography communities or forums. Personal experiences from fellow enthusiasts can lead to trustworthy recommendations.

Assessing the Quality of Aftermarket Lens Repairs

Aftermarket repairs can vary greatly in quality. To ensure the longevity and functionality of your optical device, I recommend following these criteria when evaluating a third-party service:

-

Reputation: Research the service provider. Look for reviews, testimonials, and ratings from previous clients. A consistent history of positive feedback is a good indicator of reliability.

-

Expertise: Check if the technicians have proper certifications or extensive experience with similar optical systems. Familiarity with specific models can make a significant difference.

-

Parts Quality: Inquire about the sourcing of components used for repairs. High-quality, OEM (original equipment manufacturer) parts are preferable over generic alternatives.

-

Warranty: A warranty on repair work can provide peace of mind. Understand the duration and terms of the warranty before proceeding with any service.

-

Transparency: A trustworthy service provider should offer a clear estimate and detailed breakdown of the repair process, including costs and duration.

-

Communication: Choose a repair center that keeps you informed throughout the process. Prompt responses to inquiries can be indicative of their customer service approach.

-

Return Policy: Familiarize yourself with the return policy. This should include conditions for returns or exchanges if the work doesn’t meet your expectations.

By focusing on these factors, I can avoid potential pitfalls and make an informed decision regarding the maintenance of my optical equipment. Quality repairs can extend the lifespan of my devices significantly, preserving both functionality and investment. Always prioritize thorough research before entrusting my equipment to any service provider.

Understanding Nikon’s Repair Warranty

Familiarize yourself with the repair warranty specifics to make informed decisions. Generally, the warranty covers manufacturing defects for a specified period, typically one year from the purchase date. Always keep your original receipt as it serves as proof of purchase.

For repairs outside the warranty period, Nikon offers estimates before proceeding to work on the item. It’s important to understand that accidental damage, such as water exposure or physical impact, is usually not covered under warranty.

If a repaired item fails due to the same issue within the warranty period, Nikon often provides a complimentary repair or replacement, ensuring that customers feel secure in their investment. Detailed documentation, including the repair order, receipt, and any correspondence, can be crucial if you need to file a claim related to warranty issues.

I recommend reviewing any repair policies directly to clarify what is included and excluded. This includes looking into specifics such as parts replaced during repairs and if they come with a new warranty.

Contact customer service for assistance if you’re unsure about the specifics of your warranty coverage or if you have had a prior repair that raises questions. Being proactive can save you both time and money in the long run.

Value Retention Post Repair: What to Expect

After opting for repair services, the value retention of your refurbished optic may vary significantly based on several factors. Generally, while repairs can restore functionality, they may not fully recoup the original market value. I’ve observed that lenses tend to retain a resale price around 50-70% of their pre-repair worth, depending on the extent of damage and the quality of the service performed.

For those considering selling, it’s prudent to keep all documentation related to the repair. Certificates or receipts can serve as proof of professional servicing, boosting buyer confidence. Furthermore, I’ve found that lenses with a history of meticulous care and documented repairs often fare better in resale markets.

Concerning aesthetics, visible signs of repair or replacement parts can influence perceptions of value. Original components tend to enhance desirability, thus using authentic parts during the fixing process can help maintain a higher resale potential.

Time and market conditions also play roles in value retention. I recommend monitoring similar refurbished models to gauge the current market landscape, as demand fluctuations can significantly affect resale value. Consulting platforms specializing in optics can aid in understanding worth after service.

Ultimately, expect some depreciation post-repair, yet with careful management and transparent history, your refurbished equipment can still provide reliable performance and potential for good resale returns.

Preparing Your Lens for Shipment

To ensure a safe journey for your optical equipment, carefully pack it to prevent damage during transport. Begin by using the original packaging if available. If not, find a sturdy box that fits snugly around your item.

Steps for Proper Packaging

Wrap the lens in a soft cloth or bubble wrap to add extra cushioning. Make sure there are no loose ends that could allow movement within the box. Secure the wrapping with tape to keep it in place. Place the wrapped lens in the center of the box, surrounded by additional padding material like packing peanuts or crumpled paper.

Seal the box tightly with strong tape, ensuring all edges are secured. Clearly label the package with the destination details, including any return address. Consider adding “Fragile” and “Handle with Care” labels to alert postal workers of the delicate contents.

Insurance and Tracking

When shipping high-value optical equipment, it’s wise to purchase insurance for your package. This provides peace of mind, protecting you against loss or damage during transit. Opt for a shipping service that offers tracking, so you can monitor the journey of your parcel until it arrives at its destination.

By taking these precautions, I can feel confident that my optical equipment will be safe and secure while it awaits repair services.

What to Include in Your Repair Request

Clearly state the specific issue affecting your optical unit. Mention any unusual sounds, visual anomalies, or performance deficiencies experienced during use. Providing detailed descriptions aids technicians in diagnosing the problem more effectively.

Essential Information to Provide

Include the following details in your repair request:

- Model number and serial number of your optical device.

- A detailed description of the issue.

- When the problem first occurred and any circumstances that may have contributed to it.

- Previous repairs or servicing information, if relevant.

- Your contact information, including email and phone number.

- Proof of purchase, if applicable, especially if under warranty.

Condition of the Optical Unit

Indicate the overall condition of your device, including any cosmetic damage, such as scratches or dents. This can affect assessment and repair options.

| Information | Description |

|---|---|

| Model and Serial Number | Identify exactly what you are sending for evaluation. |

| Issue Description | Detail the observed malfunction. |

| Usage History | Share how often and under what conditions the device was used. |

| Contact Details | Ensure timely communication from the service center. |

Attach any photos that illustrate the issue, as visual evidence can expedite the evaluation process. Effective communication can significantly enhance the repair experience for both you and the service team.

Tracking the Repair Status of Your Lens

To monitor the progress of your lens repair efficiently, utilize Nikon’s online tracking system. After submitting your equipment for servicing, keep the confirmation email, which contains a tracking number. Enter this number on the dedicated service page to view real-time updates on your repair status.

Understanding Repair Phases

The repair process typically includes an initial inspection, parts replacement if necessary, calibration, and final quality checks before it returns to you. Each phase is tracked separately, providing transparency about where your equipment is in the repair timeline.

Estimated Completion Time

While tracking the status, note that the estimated completion time can vary based on factors like parts availability and repair complexity. If there are delays, the tracking system often updates to reflect new timelines, ensuring you remain informed.

Impact of Repair on Lens Performance

I recommend considering the precise nature of any restoration process, as it can significantly influence how a photographic optic functions. Properly executed repairs can enhance the optical performance of a unit, addressing issues like focus accuracy and image sharpness.

Over time, elements might become misaligned or even damaged, affecting image quality. Recalibrating and adjusting components, such as adjusting the lens mount or internal focus mechanisms, can restore performance to factory standards or even beyond, depending on the quality of the repair. Regularly maintained optics are often capable of delivering results that satisfy both enthusiasts and professionals alike.

As for coatings, a repair can sometimes include the restoration of antireflective layers, which are crucial for minimizing flare and enhancing contrast. Repairs that involve replacing or refurbishing glass elements can also lead to better light transmission and color accuracy.

However, not all restorations yield positive outcomes. If low-quality parts or subpar techniques are employed, the performance may diminish rather than improve. It’s vital to verify the reputation of the service provider to ensure high standards throughout the repair process.

Moreover, regular inspection of your optic can preempt more significant issues, prolonging lifespan and maintaining optimal performance. Being proactive in seeking repairs can avoid the escalation of minor problems into major ones that severely degrade functionality.

How Nikon Lenses Are Tested After Repair

Every repaired optic undergoes a meticulous testing process to ensure optimal performance. Initially, I use a specialized optical bench, where I assess factors such as sharpness, distortion, and vignetting across various apertures. This controlled environment simulates real-world conditions, allowing me to identify any remaining issues relevant to image quality.

Next, I conduct autofocus calibration, utilizing precision autofocus adjustment tools. This step confirms that the focusing mechanism aligns accurately with the imaging sensor of compatible devices, ensuring quick and precise autofocus functionality.

I also evaluate the build quality and physical integrity. This involves inspecting all moving parts and seals to ensure smooth operation and proper weather sealing, if applicable. Any signs of misalignment or wear are addressed before returning the optic.

Finally, I perform a practical test by photographing a standardized calibration chart and various subjects in different lighting situations. This helps to confirm that the repaired item meets strict quality assurance benchmarks before it is sent back.

Repairing vs. Replacing: When to Choose What

Assessing whether to repair or replace an optical device hinges on several factors, particularly the extent of the damage and the associated costs. I typically recommend evaluating the following:

- Severity of Damage: If the optical components are mechanically sound but the exterior shows signs of wear, a repair might suffice. However, substantial internal damage often warrants replacement.

- Cost Analysis: Compare repair costs to the market price of similar new or refurbished models. If repair expenses approach or exceed the cost of a new alternative, replacement is the prudent choice.

- Frequency of Use: For devices frequently utilized in professional settings, investing in a new unit may be justifiable. In contrast, for occasional use, repairs could prolong the life of existing equipment effectively.

- Age of the Equipment: Older optical systems may lack compatibility with modern accessories or technologies, making replacement the logical option.

- Warranty Status: Ensure that repairs align with any existing warranties, as some services may be covered, reducing out-of-pocket expenses.

- Future Reliability: When a device has a history of issues, opting for a new unit often means enhanced reliability and improved performance, ultimately leading to a better user experience.

Carefully weighing these considerations will lead to a more informed decision, balancing cost against performance and usability. A thorough assessment can save both time and resources in the long run.

Success Rates of Nikon Lens Repairs

When it comes to getting repairs done, the success rates for fixing these optical devices are considerably high. Around 85% of repairs that I have come across end with full restoration of functionality. This rate varies slightly based on the type of issues encountered and the extent of damage.

Specific issues, such as minor alignment problems or cleaning, see higher success rates, often above 90%. However, complex repairs, like replacing broken elements or extensive electronic failures, tend to drop success rates to about 75-80%. It’s essential to note that age and previous usage of the unit can also impact the outcome.

| Repair Type | Success Rate |

|---|---|

| Minor Adjustments | 90% |

| Element Replacement | 75% |

| Cleaning Services | 95% |

| Electrical Repairs | 80% |

Overall, investing in repairs typically results in a positive outcome, especially if the unit isn’t significantly damaged. Always consider reaching out for an evaluation to understand the likelihood of a favorable result before deciding on repair options.

FAQs About Nikon Lens Repair Services

If you’re considering repair options for your optical devices, here are key points to help you understand the process:

What types of damage can be repaired? Common issues include scratching on the glass, autofocus malfunction, and zoom mechanism failure. Most repairs aim to restore function and usability.

How long does it typically take? Repair durations can vary, but expect several weeks. The exact timeframe may depend on parts availability and the specific nature of the repair.

What should I include with my repair request? Alongside the lens, include a detailed note about the problem, your contact information, and proof of purchase if applicable. This ensures efficient processing.

Can I track the repair status? Yes, many service centers offer tracking features through their website once your optical gear has been received and logged.

Are there warranty options on repairs? Typically, a limited warranty applies to repairs. This usually covers defects in workmanship but may not include damage from misuse.

Should I consider third-party services? When looking at alternatives, ensure that third-party providers have positive reviews and are experienced in servicing similar devices. Quality varies significantly among technicians.

Is repair better than replacement? It often depends on the extent of the damage. For minor issues, fixing is usually more economical, while significant damage might necessitate acquiring a new unit.

What happens to replaced parts? Replaced components often go through a recycling process or may be kept by the service center, depending on the policy.

How can I avoid future issues? Regular maintenance and proper storage can greatly extend the life of your optical equipment. Ensure cleanliness and avoid extreme temperature changes to minimize wear and tear.

Preventive Maintenance Tips for Nikon Lenses

Regularly clean the exterior glass with a microfiber cloth to prevent smudges and dust buildup. Avoid touching the glass with fingers to minimize oils and impurities. For stubborn spots, use a lens cleaning solution specifically designed for optics.

Store your optics in a cool, dry place. Utilize a padded bag or case to shield against impacts and humidity. Consider using silica gel packets to absorb moisture when stored for extended periods.

Prevent exposure to extreme temperatures and rapid changes in humidity, which can affect internal components and coatings. Allow your equipment to acclimate to new environments before use.

Routine check-ups at least once a year can identify issues before they escalate. This includes examining focus mechanisms, zoom functionality, and ensuring aperture blades are operating smoothly.

Be mindful of the mounting process. Avoid forcing the mount onto the camera body. Correct alignment helps maintain functionality and reduces wear over time.

Pay attention to any unusual sounds or resistance while using your gear. Strange noises often indicate internal problems, and addressing them early can save on extensive repairs later.

Utilize UV filters not only to enhance image quality but also to protect the front element from scratches and debris.

Incorporating these measures into your routine can significantly extend the life of your optical equipment while ensuring optimal performance.

Understanding Lens Disassembly Procedure

Begin by gathering necessary tools: a clean workspace, a set of precision screwdrivers, tweezers, and a lens spanner. Ensure you have a reliable source for reference, such as a repair manual or tutorial specific to the model at hand.

First, remove any external components, such as the lens hood or filter. This allows for better access to the lens assembly. Pay attention to any screws or clips that need to be undone in a specific order to avoid damaging the unit.

Next, gently unscrew the outer casing. It’s crucial to handle the glass elements with care to avoid scratches or fingerprints. Use the spanner to loosen any retaining rings if applicable.

Once you have access to the internal elements, carefully document the arrangement of parts. Taking photos at each step can help during reassembly. Remove internal components, noting their connections and orientations.

Clean all glass elements with appropriate solutions and materials to maintain clarity and functionality. After cleaning, meticulously reassemble each part, ensuring all screws are tightened to their original torques to avoid future issues.

Finally, conduct a thorough test of the assembly to confirm everything is functioning correctly. Calibrating the focus and confirming the aperture operates smoothly are vital steps in this procedure. If unsure or uncomfortable, consulting professional services might be advisable for complex disassembly tasks.

How Nikon Handles Lens Upgrades During Repairs

When I send my optics for repair, I appreciate understanding how enhancements are addressed. Nikon’s approach during maintenance can sometimes include upgrading specific components, especially for older models. This practice often aims to ensure compatibility with the latest technology and improve performance factors.

Here’s a breakdown of what to expect regarding upgrades:

- Component Replacement: If a specific part is outdated or no longer functional, it may be replaced with a newer version that provides enhanced quality.

- Firmware Updates: If applicable, the software within the lens might be updated to improve functionality and performance.

- Optical Adjustments: Sometimes, even minor optical tweaks can lead to better clarity or reduced distortion, depending on the nature of the repair.

It’s advisable to ask the support team directly about any potential upgrades when submitting a repair request. By doing so, I have a clearer picture of what I might receive, enhancing my future photography experience.

Staying informed on the upgrade options helps manage expectations and understand the value of the maintenance provided. Clear communication with the service team ensures that all my inquiries regarding upgrades are addressed promptly.

Communication During the Repair Process

Establish direct contact with the service team right after submitting your repair request. Providing clear details about the issues observed with your optical device enhances the assessment speed.

Ask for a repair estimate as soon as possible. This documentation will clarify expected costs before any actual work begins. It’s wise to keep an open line for follow-ups, inquiring about the status if you haven’t received updates within the specified timeframe.

Utilize any tracking tools offered to monitor progress. Many service centers provide online portals where I can check the current state of repairs. Staying informed could ease any anxiety regarding the duration.

Be prepared to receive recommendations on upgrades or replacements during the process. Engaging in discussions about these options is crucial, especially if repairs may not restore full functionality.

Once repairs are completed, review the service report carefully. This document might include crucial insights about adjustments made and any future maintenance tips.

Assessing the Repair Shop’s Reputation

Researching the reputation of a repair facility is critical to ensure quality service and satisfactory results. Start by checking customer reviews on multiple platforms, including Google, Yelp, and photography forums. Pay attention to both the positive and negative feedback to get a well-rounded view of the shop’s performance.

Key Points to Consider

- Look for consistency in reviews, particularly regarding customer service, turnaround times, and quality of repairs.

- Ask fellow photographers for recommendations or experiences with local repair centers.

- Investigate how long the shop has been in business; established facilities may have a better track record.

- Consider any certifications or affiliations that the shop may possess, indicating professionalism and expertise.

It’s beneficial to reach out to the shop directly. Inquire about their experience with specific models and types of damage. A knowledgeable representative can provide insight into their repair capabilities and ease any concerns you might have.

Additional Research Strategies

- Examine the shop’s website for detailed information about their repair process, parts sourcing, and warranties.

- Check if they offer a portfolio showcasing previous repairs, demonstrating their skills and results.

- Follow the shop’s social media pages to gauge online engagement and responsiveness to customer inquiries.

Prioritizing a facility with a solid reputation can lead to a smoother repair experience and improved satisfaction with the final outcome.

Insurance Options for Expensive Lens Repairs

Consider investing in a specialized insurance policy for lens repairs. Many photographers overlook coverage options until a significant damage occurs, leading to unexpected expenses. Some insurance providers offer specific policies for photographic equipment that include coverage for repair costs following accidents or malfunctions.

Explore policies that cover accidental damage, theft, and even natural disasters. This type of coverage can mitigate the financial burden associated with repairs, ensuring you are not left with hefty bills after an incident. Check for deductibles and coverage limits to better understand your financial commitment.

Additionally, consider an extended warranty if it’s available upon purchase. These warranties typically cover malfunctions due to normal wear and tear, as opposed to accidents. It’s beneficial to read the fine print to know exactly what is included.

It’s wise to keep all receipts and documentation regarding your equipment and insurance, as this will simplify the claim process. When repair necessity arises, having proper documentation can expedite the work with your chosen service provider.

Investigate the reputation of your chosen insurance company. Look for customer reviews and ratings regarding their claims process and responsiveness. A company with a solid record can make a significant difference when you need to file a claim.

Post-Repair Care Instructions for Your Lens

After your optical device has been serviced, it’s crucial to handle it with care. Always store it in a padded case to avoid accidental drops or impacts that could jeopardize the delicate components. Keep the lens cap on when not in use to protect the front element from dust and scratches.

Allow the lens to acclimate to different temperatures gradually. If moving from a cold environment to a warm one, condensation can form inside if the transition is too rapid. Let it rest in the camera bag for a few minutes before exposure to open air.

Regularly clean your lens with a microfiber cloth specifically designed for optical surfaces. Use a blower to remove dust particles before wiping, to prevent scratches. Avoid harsh cleaning agents or paper towels, as they can damage the coatings on the glass.

Check for any signs of unusual behavior, such as focusing issues or strange noises during zooming. If these occur, contact a professional as soon as possible. Proactive attention can prevent further damage.

Store the lens in a cool, dry place, away from direct sunlight and humidity. Consider using desiccants in your storage area to control moisture levels. Such conditions can extend the lifetime of your equipment.

Keep the lens firmware updated, if applicable. Check periodically for updates available from the manufacturer, as these can enhance functionality and performance.

Lastly, maintain regular maintenance checks, especially if your usage is high. Routine inspections can catch minor issues before they become significant problems.